Unknown Facts About PEEK Plastic - High Mechanical Properties - Supply Services

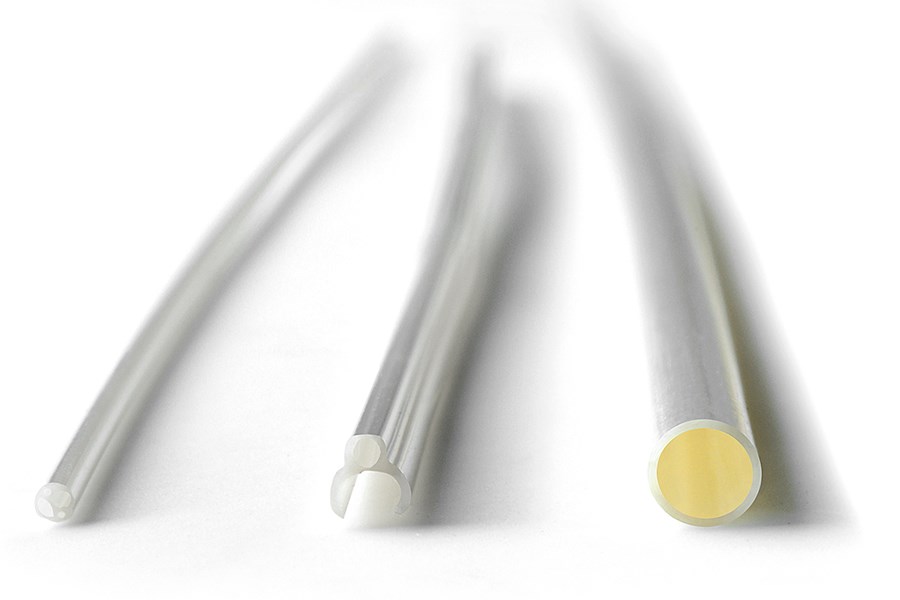

Clarity and Color The natural color for PEEK machining is tan, but black is also readily available. PEEK thin movie can be translucent or clear when in an amorphous state. Cost and Schedule PEEK sheets, rods, tubes, and movies are widely offered for machined parts as extruded products. PEEK plastic is offered in a range of small size tubing items for carrying liquids and capable of high chemical resistance.

Additionally, general-purpose machine grade, USP class 6 grade, and implant grade are offered for PEEK parts. Additional Info is a more expensive material than a number of the other compounds Managed Fluidics utilizes. At first, it was only readily available from Victrex with their unfilled resin number referred to as 450g. Presently, additional producers are competing in the market, which helps to enhance the cost point.

Top Guidelines Of PEEK Injection Molding Vs PEEK Machining - Blue-Reed, LLC

Machining PEEK Plastic Many producers select PEEK plastic as a manifold material. It is resistant to many natural and inorganic chemicals, except for concentrated nitric and sulphuric acids. In addition, it uses extremely low moisture absorption and remarkable wear and abrasion resistance for longer-lasting items. For heat-related applications, PEEK has among the finest continuous service temperatures at up to 425F without any long-term loss in physical properties.

It does have a lower heat deflection temperature of 306F. A PEEK machined part is still practical in that range however will lose some of its strength due to softening. PEEK Optima's walls can be made as thin as 0. 0008 with tolerances to 0. 0002. Downsides of PEEK Plastic Aside from its high cost, the primary disadvantages of PEEK plastic are its low resistance to UV light and the requirement to process it at heats.

PEEK & engineering plastic fasteners - Solid Spot for Dummies

Uses for PEEK Some ranges of PEEK plastic are made with pre-qualified biocompatible products and are FDA approved, making them ideal alternatives for life science applicati